Welcome to our websites!

NEWS

-

Static elimination measures for clean rooms

The static elimination measures for clean rooms mainly include selecting suitable floor materials, using static elimination equipment, controlling indoor humidity, and strengthening personnel anti-static training. First of all, selecting suitable ground materials is an important part of static e...Read more -

Static electricity problem and solution for plastic products

Plastic products usually have high insulation properties, so the plastic industry is also a high-risk area for static electricity problems. Effective static elimination treatment must be carried out in the bag making area, molding, plastic bottle production, masterbatch transportation and other p...Read more -

Static elimination measures for electronic purification workshop

In modern industrial production, electronic clean rooms play a crucial role, especially in the production process of high-tech products such as semiconductors, precision instruments, and electronic components. However, static electricity has always been a major challenge faced by such workshops. ...Read more -

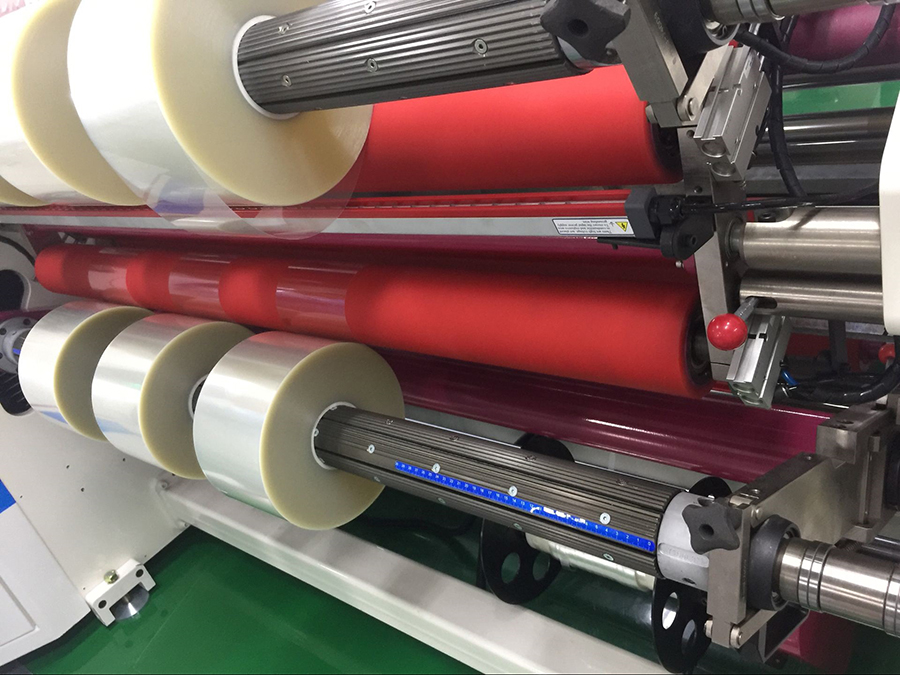

Solving the static electricity problem during tape cutting

During the entire slitting process, due to factors such as slitting, tension, and friction, a large amount of static electricity will accumulate, which can easily generate sparks, electric shocks, and dust adsorption. The static electricity repels or attracts each other, resulting in slipping of ...Read more -

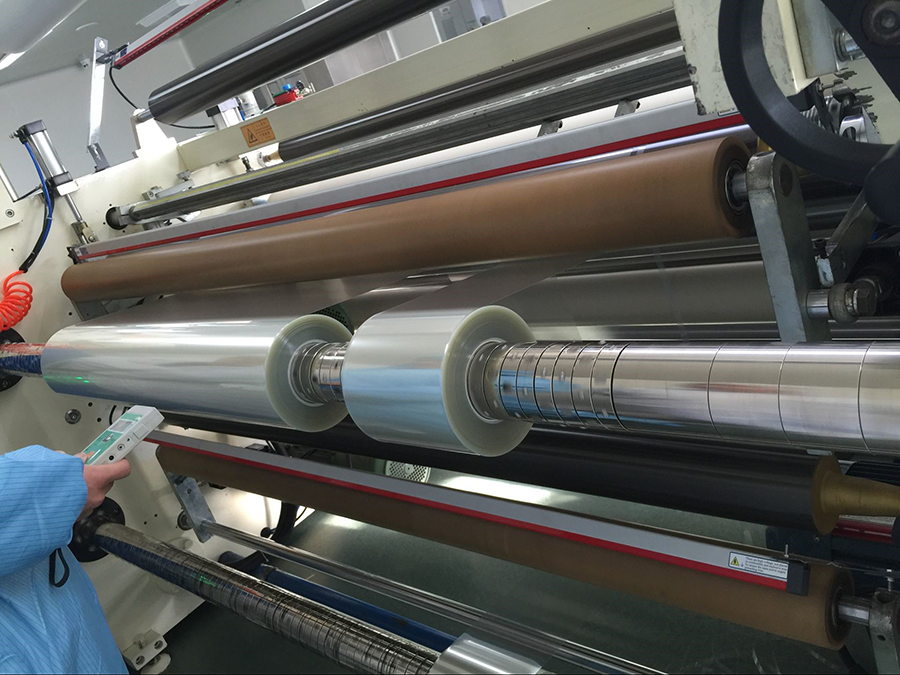

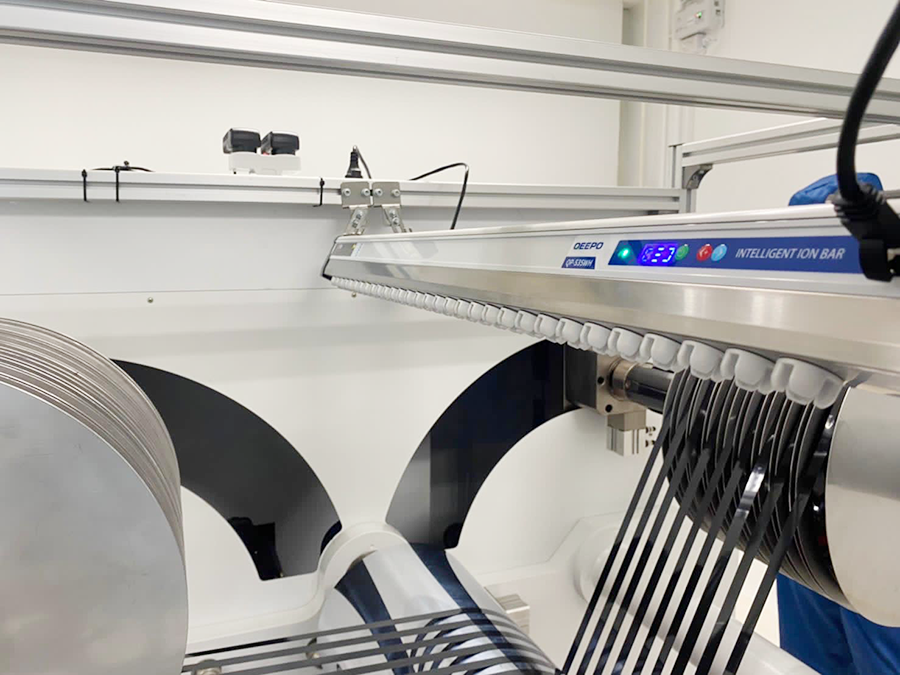

Electrostatic elimination during film rewinding process

Film extrusion or blowing lines usually carry extremely high static electricity exceeding 200KV, which can cause the following problems: 1. Operators suffer from electric shock, causing discomfort 2. High static film production with film rolls 3. Attract dust one meter away and contaminate the fi...Read more -

Static eliminator bar solves static electricity problems in inkjet printing

During the extrusion process of profiles, containers, boxes, etc. will generate high static electricity, which can cause many problems for inkjet printing systems: 1. A large amount of dust is adsorbed onto the printing material. 2. Ink jet deviation, resulting in needle holes or white spots, lea...Read more -

the electrostatic problem in the EVA film manufacturing process in the photovoltaic industry

EVA is one of the most critical packaging materials in the production process of solar modules, which seals the upper and lower covers of the battery cells in the middle to protect them; EVA has a high transmittance after melting, which can increase the incidence rate of light and increase the ou...Read more -

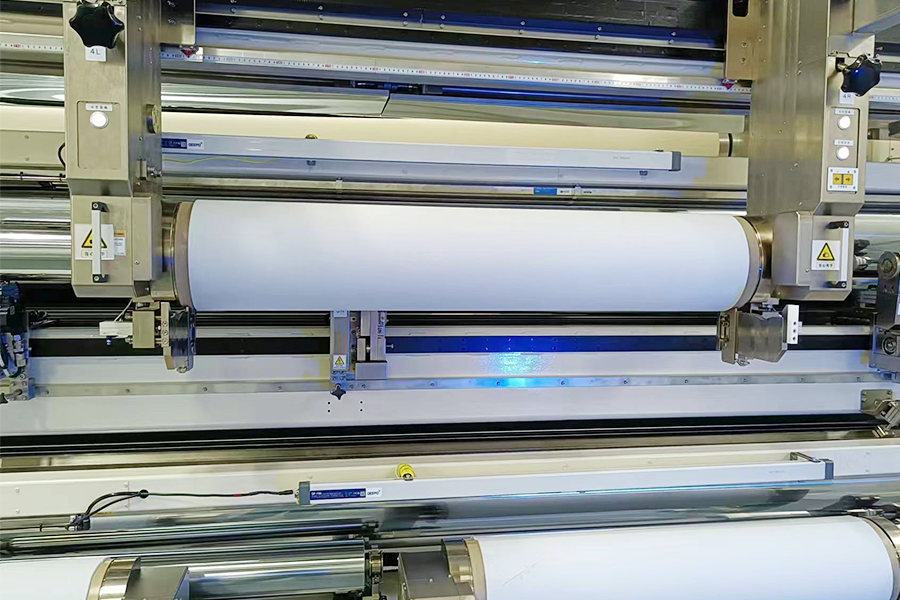

The harm and solution of static electricity in rewinding

The application of unwinding runs through all industries, whether it is plastic film, paper, or textiles. In the process of rapid winding and unwinding, a large amount of friction, peeling, and squeezing will occur between the material and the roller, causing static charges of different electric...Read more -

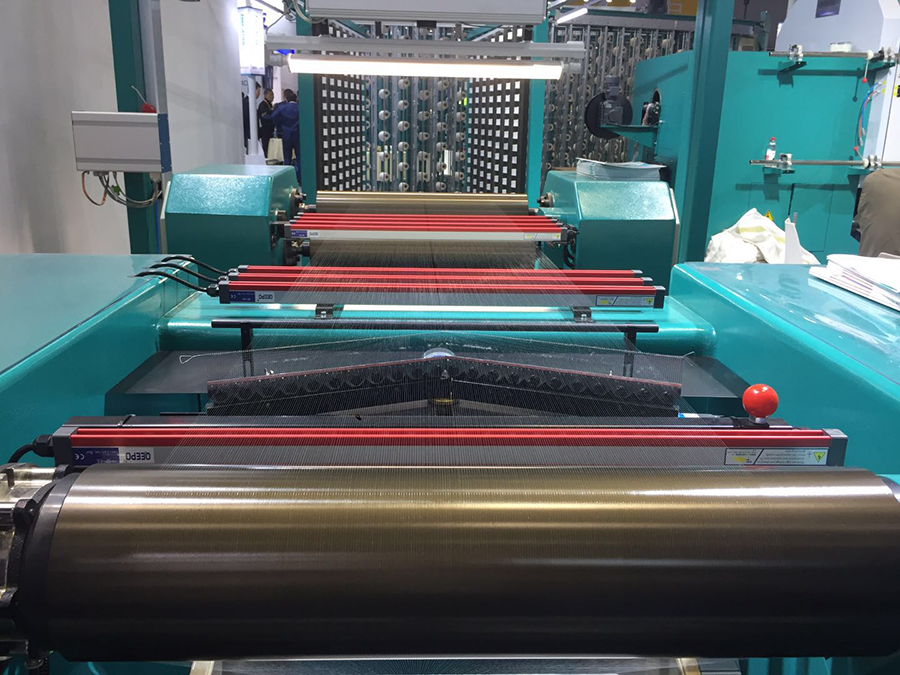

Solution to electrostatic problems in the textile industry

During the textile production process, static electricity and dust can seriously affect product quality. When the air is dry, static electricity will slowly accumulate, and the friction between the machine and the yarn will generate more static electricity, causing textile production to be unable...Read more -

The Harm of Static Electricity to Industrial Production

The harm of static electricity to industrial production is mainly manifested in hindering production or reducing product quality. In the textile industry and industries with fiber processing, especially in the production and treatment processes of synthetic fibers such as polyester and acrylic, s...Read more -

Six common printing methods to solve static electricity

In order to ensure that the static electricity will not affect the product quality in printing, the production with quality and quantity guaranteed, and at the same time to avoid the occurrence of fire. We must pay strict attention to static electricity and take effective measures and Countermeas...Read more -

What are the consequences of static electricity on printing?

In the actual production process, if printing products are affected by static electricity, there are four common problems: burrs, missing printing, graphic dots, stripes and water drops, which will seriously affect the final quality of printing products. 1、 Burrs caused by static electricity Wh...Read more