In order to ensure that the static electricity will not affect the product quality in printing, the production with quality and quantity guaranteed, and at the same time to avoid the occurrence of fire. We must pay strict attention to static electricity and take effective measures and Countermeasures to eliminate the adverse effects of static electricity.

Here are some common solutions:

1. When installing the printing machine, the grounding wire must be installed, and the ink circulating pump should also adopt the grounding wire.

2. Control the environmental sanitation of the workshop, keep it clean and reduce dust.

3. The temperature and dry humidity of the workshop should be well controlled. The temperature of the workshop should preferably be controlled at the standard temperature of 18 ℃ – 25 ℃, and the humidity should be between 55% and 75%. After the workshop is dry, the humidity can be increased by watering or mopping the floor.

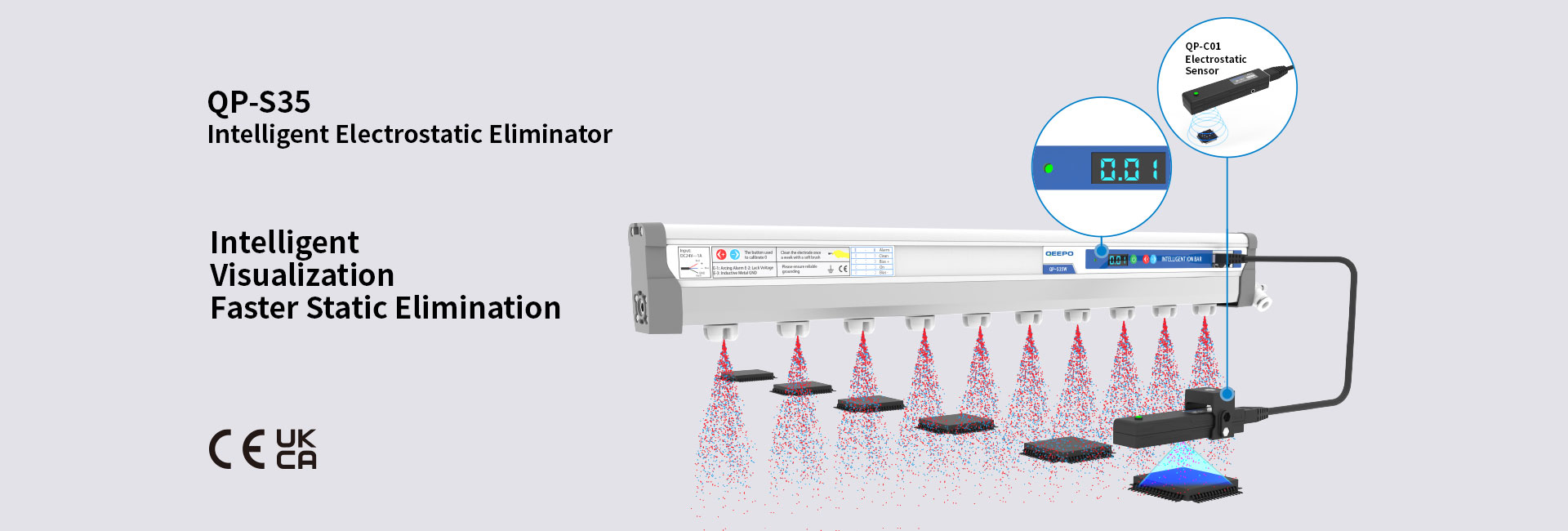

4. Install electrostatic eliminators in various color parts of the printing machine. High end printing machines are equipped with electrostatic eliminators, and those that are not installed should be purchased and installed by themselves.

5. The printing manufacturer should prepare antistatic agent by itself. In case of serious static electricity, it should be added to the ink to eliminate static electricity.

6. In case of burring and missing printing, the working viscosity of printing ink should be increased, and slow drying diluent should be selected to reduce the machine speed.

Post time: Jul-28-2022