During the textile production process, static electricity and dust can seriously affect product quality. When the air is dry, static electricity will slowly accumulate, and the friction between the machine and the yarn will generate more static electricity, causing textile production to be unable to proceed normally. Accidents such as broken ends, flying flowers, and yarn entanglement often occur, which reduce production efficiency and product quality. Therefore, quickly and effectively eliminating static electricity becomes a guarantee of textile product quality.

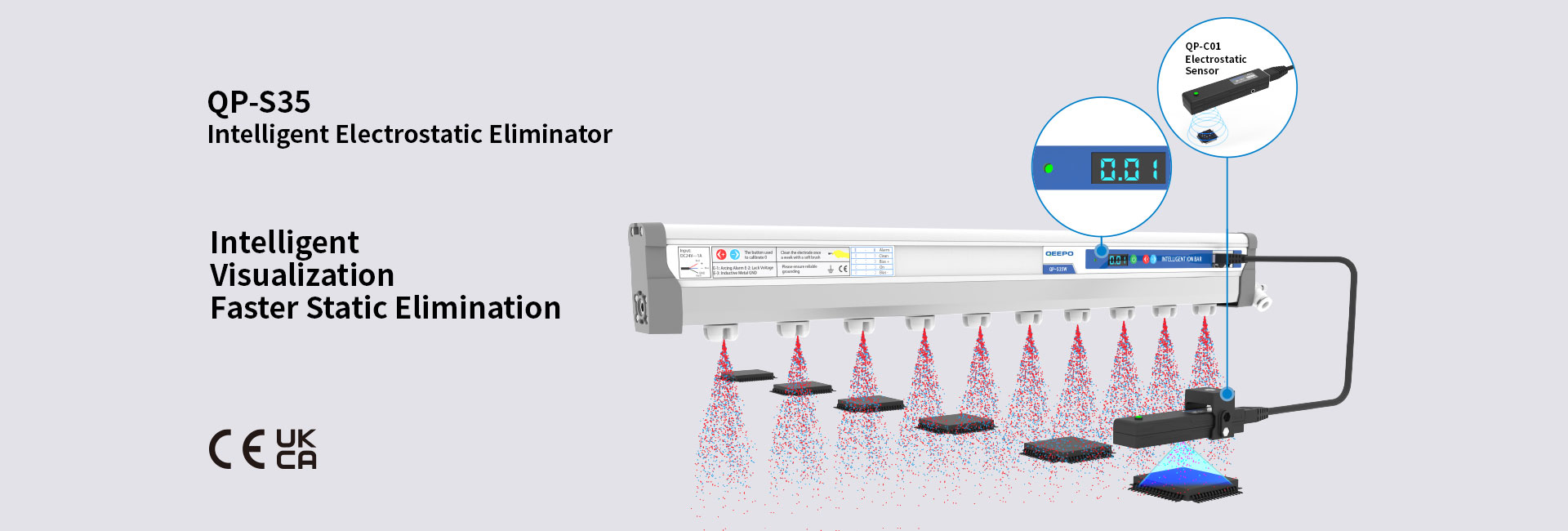

The commonly used static electricity control equipment for static electricity elimination is the static electricity elimination rod, which generates positive and negative ions that help dissipate the static charge on the processed material. The static electricity elimination rod can generate a large number of ions with positive and negative charges, which are blown out by compressed air at high speed and can neutralize the charge on the object. When the surface charge on the object is negative, it will attract positive charges in the airflow. When the surface charge on the object is positive, It will attract negative charges in the airflow, thereby neutralizing the static electricity on the surface of the object, achieving the goal of eliminating static electricity.

Here are the static electricity issues and solutions in the textile industry that we have organized:

1. Elimination of static electricity in textile carding machines

Problem: During the carding process, static electricity can cause fibers to tightly adhere to the upper and lower rollers, causing frequent entanglement and making it difficult to form strips, seriously affecting the quality of textile fabrics and even affecting the normal production process.

Solution: Install an electrostatic elimination rod 500mm above the conveyor belt.

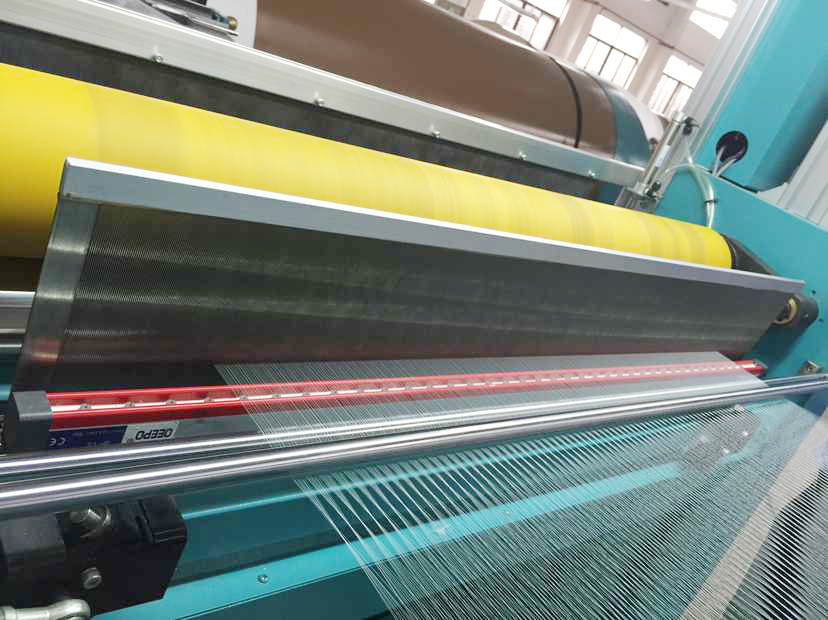

2. Electrostatic elimination of warping machine

Problem: High speed yarn carries high static electricity, which can cause yarn entanglement, repulsion, and breakage.

Solution: Install an electrostatic elimination rod above the warped yarn to eliminate static electricity.

3. Elimination of static electricity on the creel frame

Problem: During the processing of yarn, static electricity is generated and dust is attracted, resulting in uneven yarn lines, broken ends of fine yarn, and an increase in yarn defects.

Solution: Each layer of yarn that passes through the reel needs to undergo static elimination treatment, and a stepped installation of static elimination rods is required.

4. Electrostatic elimination of winding machine

Problem: Static electricity causes the yarn to fuzz up until it breaks, making it impossible to double twist the silk thread.

Solution: Install an electrostatic eliminator to eliminate static electricity.

5. Static elimination of inspection machine

Problem: After unwinding, the fabric passing over the testing platform will generate static electricity, causing the fabric to stick to the testing platform and causing electric shock to the testing personnel.

Solution: When the textile leaves the inspection table, use an electrostatic elimination rod to eliminate static electricity, prevent electric shock, and prevent the fabric from adsorbing on the inspection table.

6. Static elimination of stretching and shaping

Problem: When the fabric is walking on the machine, the temperature increases and friction with the rollers generates a large amount of static electricity, leading to fabric adhesion and electric shock problems.

Solution: Use an electrostatic elimination rod to be installed 100-500mm above the center of the fabric to eliminate static electricity. If there is static electricity on both sides of the fabric, it is necessary to install static elimination rods on both sides.

Post time: Aug-22-2023