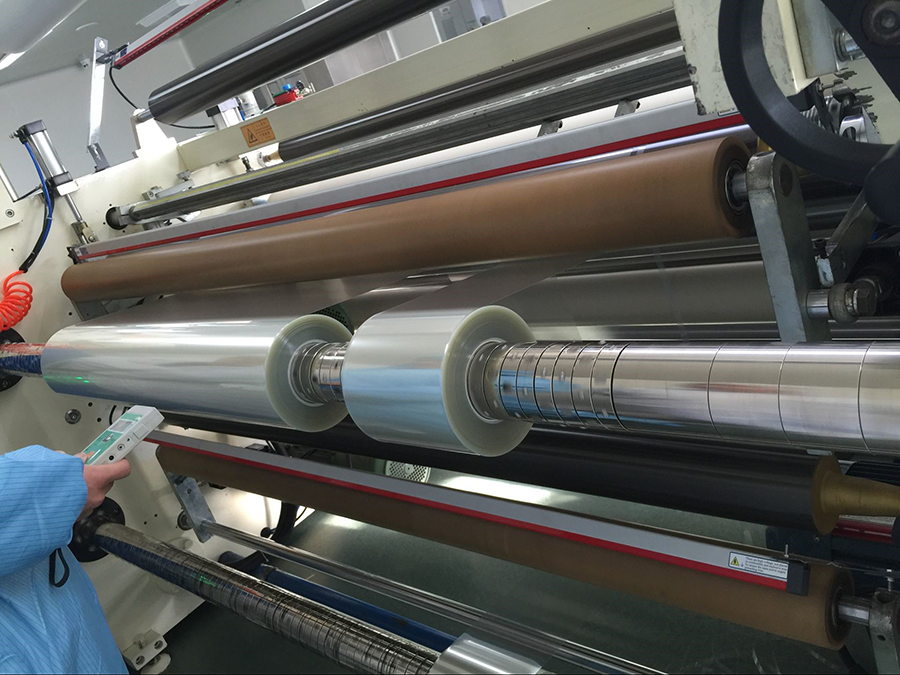

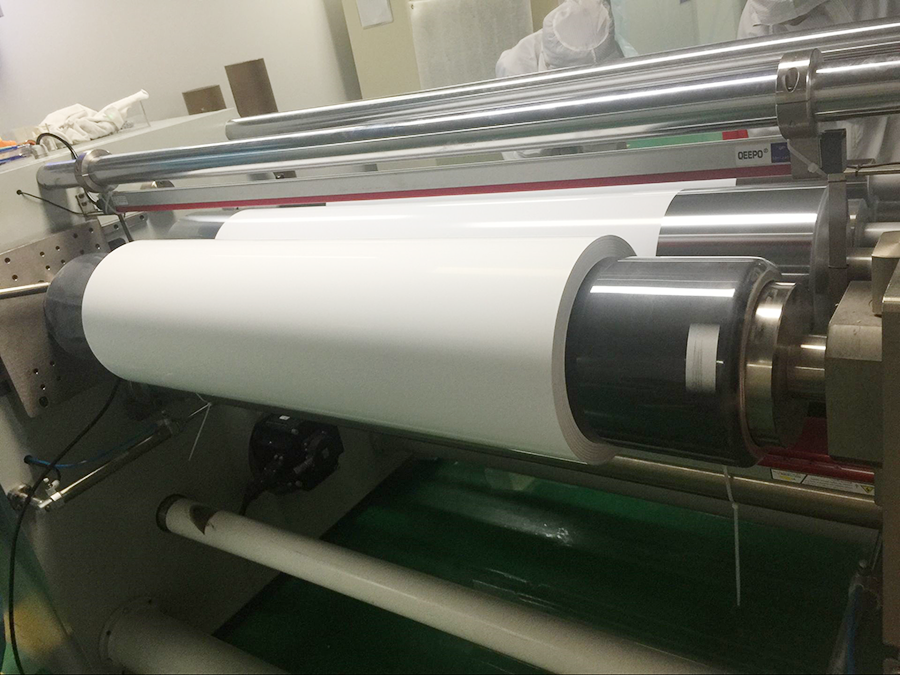

The application of unwinding runs through all industries, whether it is plastic film, paper, or textiles.

In the process of rapid winding and unwinding, a large amount of friction, peeling, and squeezing will occur between the material and the roller, causing static charges of different electrical properties to accumulate on the surface area of the object. The faster the speed and time, the greater the accumulated static electricity, and the greater the electrostatic problem:

1. The static electricity value in the winding and unwinding area can reach several hundred thousand volts, and workers are often troubled by electric shocks during operation. In severe cases, it can cause short-term paralysis and affect their work enthusiasm;

2. High static electricity can cause arc or spark discharge, and can cause fires in the presence of flammable substances in the production environment, such as near the coating head of the coating machine, where such phenomena occur frequently;

3. High static electricity will attract dust and fine hairs in the air, causing a decrease in product cleanliness;

4. When the static electricity in the winding is too high and a large amount of static electricity is coupled inside the product, customers may encounter problems such as adhesion, improper separation, electric shock, etc. during use, which affects customers’ trust in the product and leads to a serious decline in product sales.

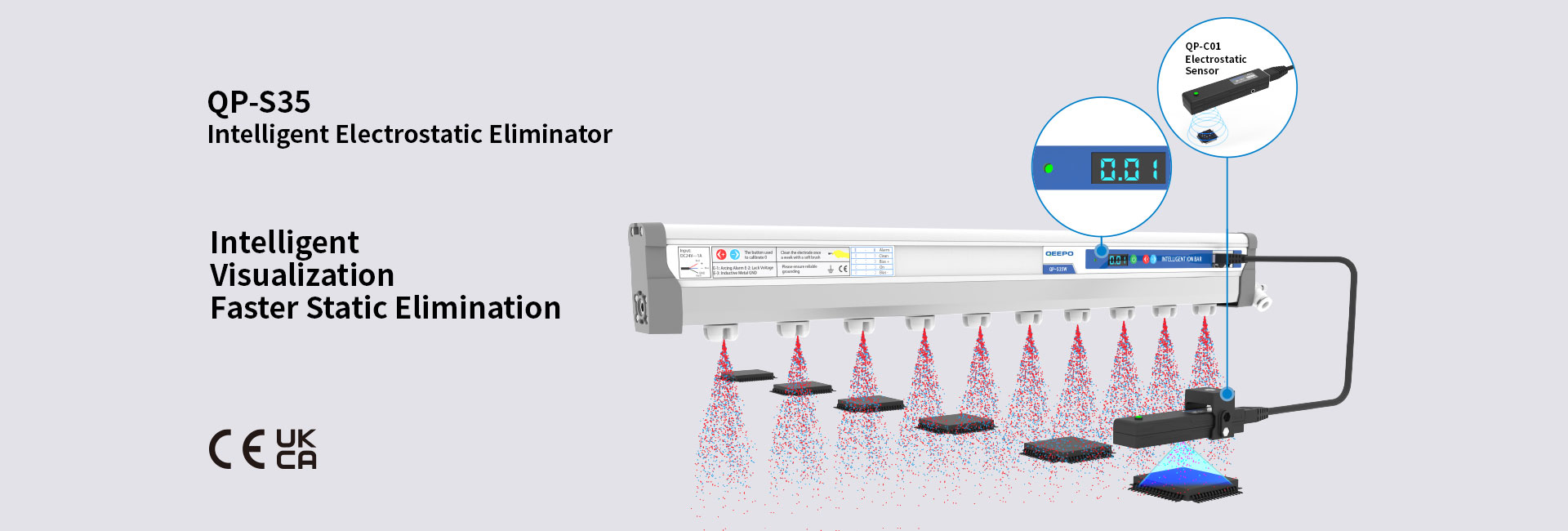

Solution to static electricity in winding and unwinding:

Installing an electrostatic eliminator is the quickest way to deal with static electricity issues during winding and unwinding. It has fast static removal speed and is easy to install

Post time: Sep-11-2023