The harm of static electricity to industrial production is mainly manifested in hindering production or reducing product quality.

In the textile industry and industries with fiber processing, especially in the production and treatment processes of synthetic fibers such as polyester and acrylic, static electricity issues are particularly prominent. For example, during the drawing process, each wire needs to be squeezed out of a small hole with a diameter of several tens of micrometers, which generates strong static electricity. Due to the effect of static electricity, the wire can float, bond, entangle, and hinder normal production. In the process of weaving, printing and dyeing, due to the adsorption effect of electrostatic force, it may adsorb dust, reduce product quality, and even affect the winding, making the winding not tight.

In the process of powder production and processing, static electricity not only brings fire and explosion hazards, but also reduces production efficiency and affects product quality. For example, during powder screening, the adsorption of fine powder due to the action of electrostatic force can reduce the mesh size and reduce production efficiency. In the process of powder pneumatic conveying, due to the action of electrostatic force in certain parts of the pipeline, some transported materials accumulate, which can also reduce production efficiency. Moreover, due to the electrostatic effect, the agglomerated powder separates and mixes in the product, which can affect the quality of the product. When measuring powder, the electrostatic adsorption of the measuring instrument on the powder can also cause measurement errors. When bagging powder, due to the electrostatic repulsion force, the powder flies around, causing both powder loss and environmental pollution.

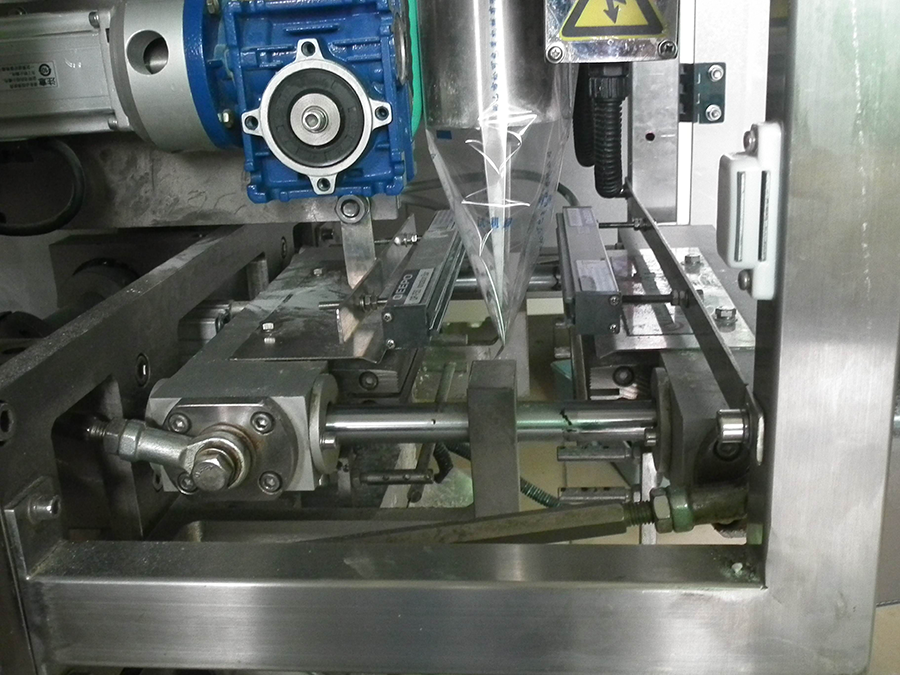

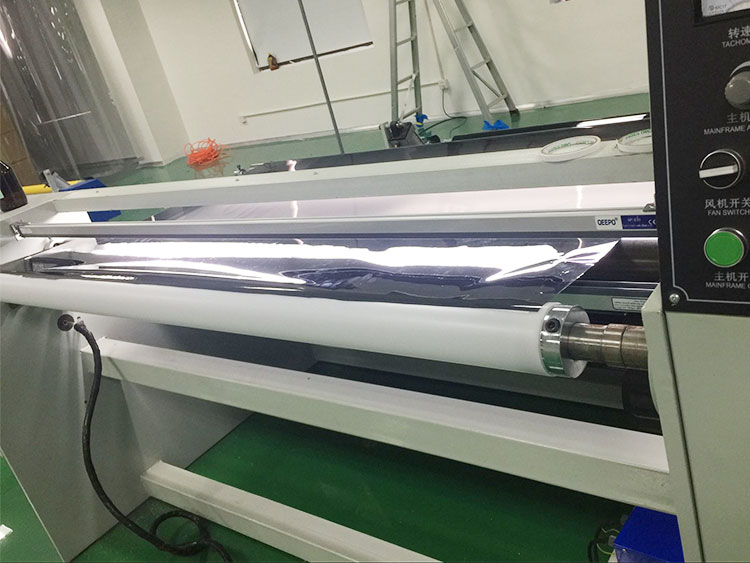

In the plastic and rubber industries, a large amount of static electricity is generated due to the friction between products and rollers, as well as the extrusion or stretching of products. On the one hand, there is a risk of fire and explosion, and on the other hand, due to the inability of static electricity to dissipate quickly and the adsorption of a large amount of dust, a lot of time has to be spent cleaning. In printing and painting processes, static electricity can greatly reduce the quality of the product by causing ink to move. When wrapping plastic film, it may not be tightly wrapped due to the repulsive force of static electricity.

In the printing industry, due to the static electricity on paper, its movement can be hindered, which may prevent the paper from separating and sticking to the conveyor belt, resulting in inaccurate overprinting, uneven folding, ink movement under pressure, and reduced printing quality.

In the photosensitive film industry, due to the high-speed friction between the film and the roller shaft, the static voltage of the film can reach thousands or even tens of thousands of volts. Once electrostatic discharge occurs, even low energy corona discharge can make the film photosensitive and scrap. In addition, charged films can adsorb dust due to electrostatic attraction and reduce film quality. Coating worker

Due to the influence of electrostatic force, uneven coating may occur.

In the food processing industry, powdered raw materials can be adsorbed on the inner wall of process equipment due to electrostatic action, often unable to be removed temporarily. However, when converting to another type of food, these residual raw materials on the inner wall of the equipment may fall off, thereby reducing food quality.

Post time: Aug-08-2023