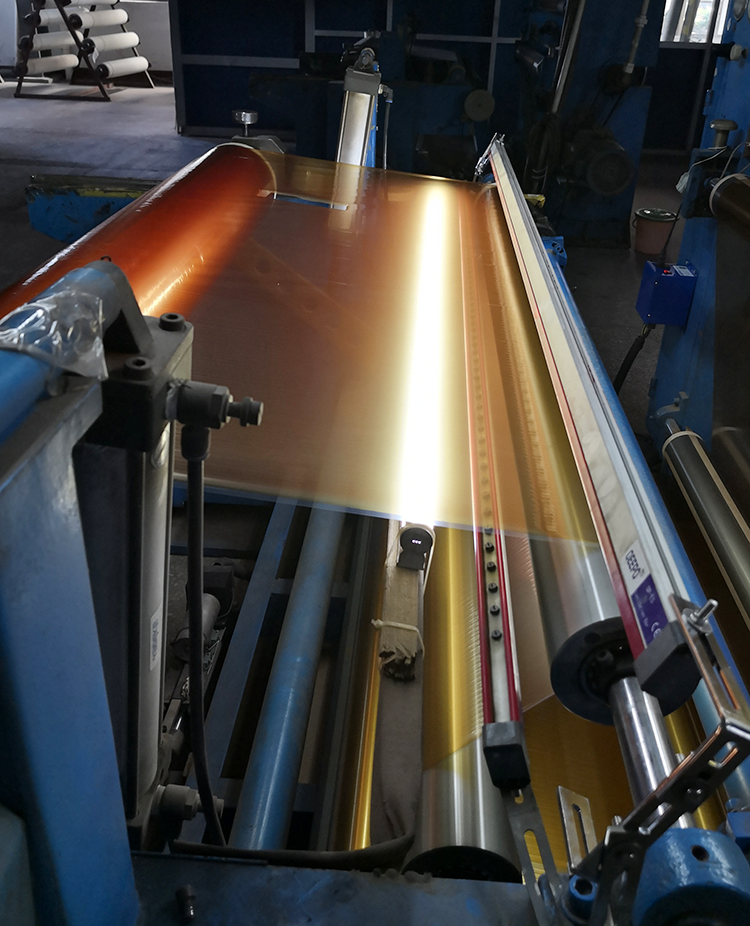

In the printing industry, according to customer requirements, after the product printing production must be bronzing. Hot stamping process needs to use electrochemical aluminum material to achieve.

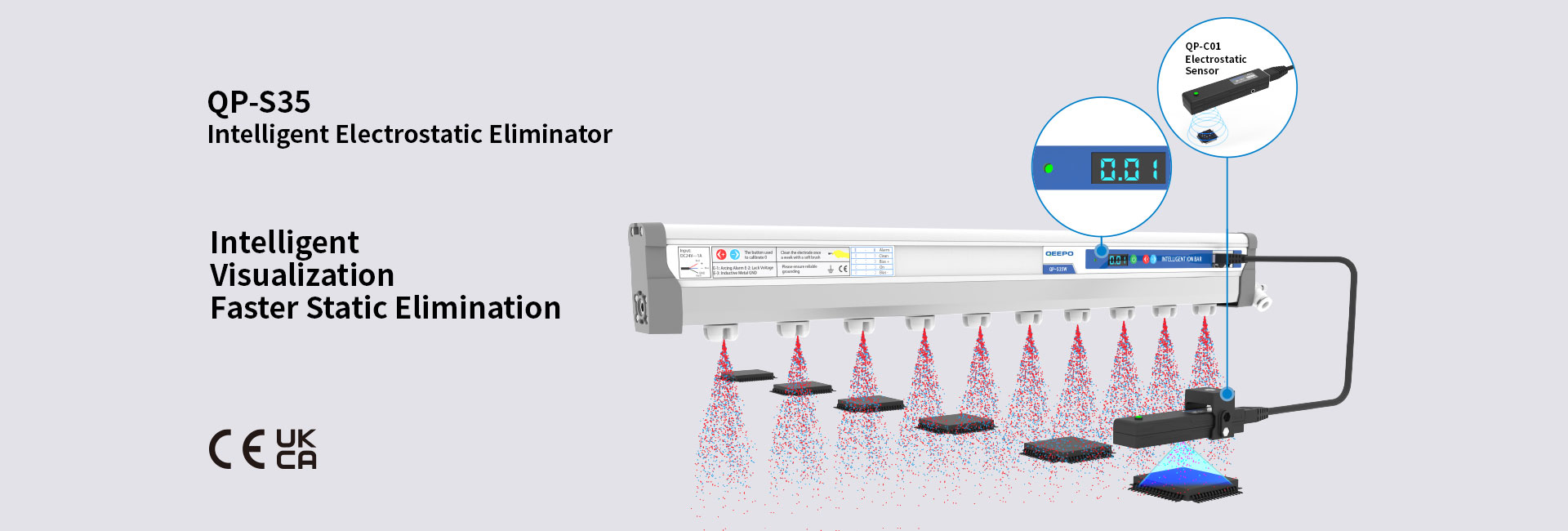

In the process of manufacturing, there will be electrostatic problems in the winding. Today, I would like to share with you the electrostatic eliminator installed in the winding position.

Rewinding and unwinding is applied throughout all industries, whether it is plastic film, paper or textiles. In the process of fast rewinding and unwinding, there will be a lot of friction, peeling and extrusion between the material and the roller, which will make the surface area of the object accumulate different electrostatic charges, and with the increase of speed and time, the electrostatic value will continue to accumulate, resulting in a very serious electrostatic problem.

Qp-es static eliminator of Qipu static electricity is installed in the winding process of electrochemical aluminum coating. It is easy to install, equipped with high-voltage power supply, with fast electrostatic removal speed and long service life, which can solve the static electricity generated in the winding process.

Please contact qeepo for more information about electrostatic removal.

Post time: Jul-01-2021