Common electrostatic hazards in winding and unwinding!

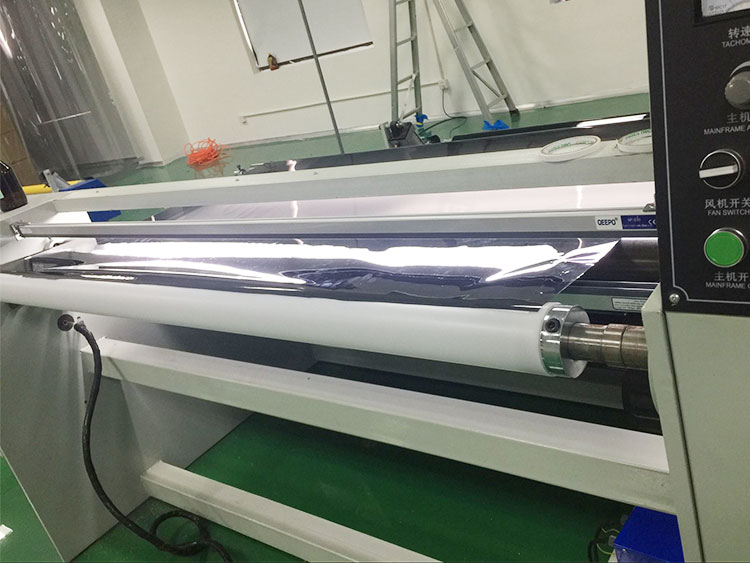

The application of rewinding and unwinding runs through all industries, whether it is plastic film, paper, or textiles. In the process of rapid rewinding and unwinding, a lot of friction, peeling and extrusion will be generated between the material and the roll, so that the surface area of the object will accumulate electrostatic charges with different electrical properties, and the electrostatic value will continue to accumulate with the increase of speed and time, causing serious electrostatic problems:

1. The electrostatic value in the winding and unwinding area can reach more than 100000 volts at most. Workers often suffer from electric shock during operation, which can cause short-term paralysis in serious cases, affecting workers’ work enthusiasm;

2. High static electricity will cause arc or spark discharge, and fire will be caused when there are combustible substances in the production environment. For example, the area near the coating head of the coater is where such phenomena occur frequently;

3. High static electricity will attract dust and fine hairs in the air, resulting in a decline in product cleanliness.

4. When the winding static electricity is too high and a large number of static electricity is coupled inside the product, customers will have problems such as adhesion, unsuitable separation, electric shock, etc., which will affect customers’ trust in the product.

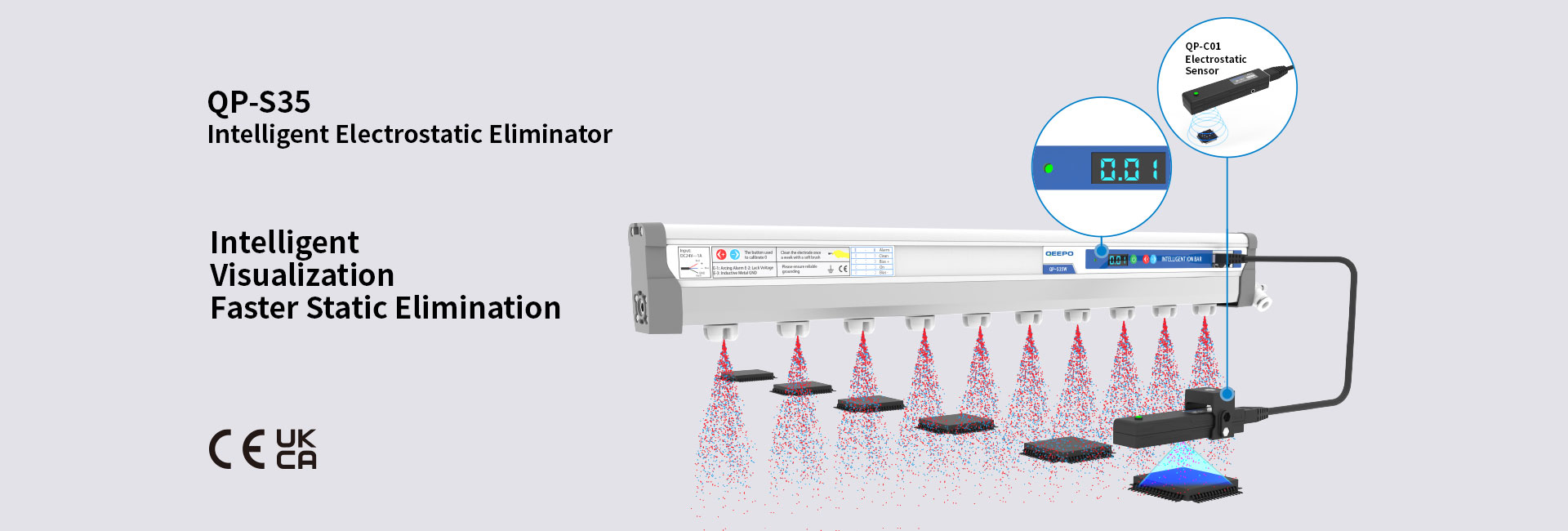

There are many ways of rewinding, including central winding, pressure roll winding, tower winding, etc. Different rewinding ways have different ways of eliminating static electricity.

Please contact qeepo for specific electrostatic removal solutions, and we will provide electrostatic solutions according to your customer’s site

Post time: Jul-05-2022